Achieved Accuracy of 2/100mm without Machining Processes

Direct casting is an ideal casting technique for small-lot production or products in the prototype examination stage. Uniquely manufactured direct casting proudly provides amazing completion accuracies of 2/100mm, without performing any machining processes, which are unavoidable with common casting methods. Accordingly, this allows for great reductions in the product delivery period, not only reductions in the cost per product, which could not be avoided in small-lot production. The predominant points of direct casting are not only the high dimensional accuracy, costs and merits of a shorter delivery. The basic quality of casting products, such as compatibility with thinner wall thicknesses, shrinkage cavities, pinholes, grain size and the smoothness of the casting surface which greatly influences the basic quality of cast products, also provides values which greatly exceed common casting techniques.

Problems in Conventional Manufacturing Methods

There was a need to reduce costs related to the machining processes and solve the problem of long delivery times.

Due to the lack of compatibility with complicated thinner wall thicknesses, it was difficult create complicated moldings without any machining.

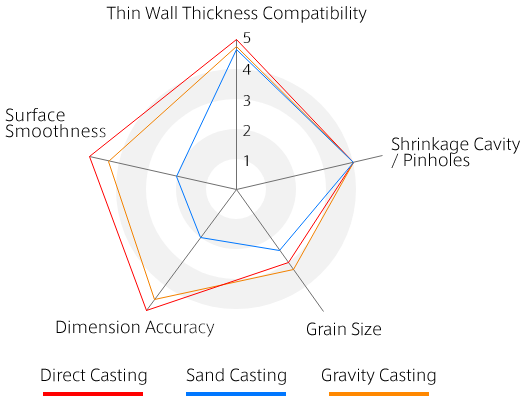

Quality Performance Comparison between Direct Casting and Other Castings

* Since Direct Casting is for small-lot production and prototype casting, the quality performance was compared with other similar casting methods.

1. Super-High Precision

Achieved a 2/100mm finished dimension without a machining process. This is ideal for small-lot production where there is a need to reduce the costs of machining processes and prototypes, which require various types of production for a single product.

2. Thin Wall Thickness Compatibility

Achieved a thin wall thickness compatibility, which is equivalent to conventional casting methods where finishing was performed by a machining process. The ability to handle complicated moldings using an effective molten flow is also a great feature of direct casting.

3. Grain Size

Achieved precisely arranged grain sizes. Even in prototypes which require strength tests, etc., as well as the quality control of small-lot production, the grain size of high definition direct casting fully demonstrates its function as a benchmark to accurately determine if a prototype can be moved to mass production.